OXYGEN Vegetal: i film protettivi e di processo eco-sostenibili

Introducendo polietilene o polipropilene biobased, la gamma OXYGEN Vegetal è la soluzione migliore per i produttori che desiderano ridurre il loro impatto di CO2.

Questa gamma offre film di origine naturale non fossile (scarti e residui di oli vegetali), prodotti secondo il mass balance approach.

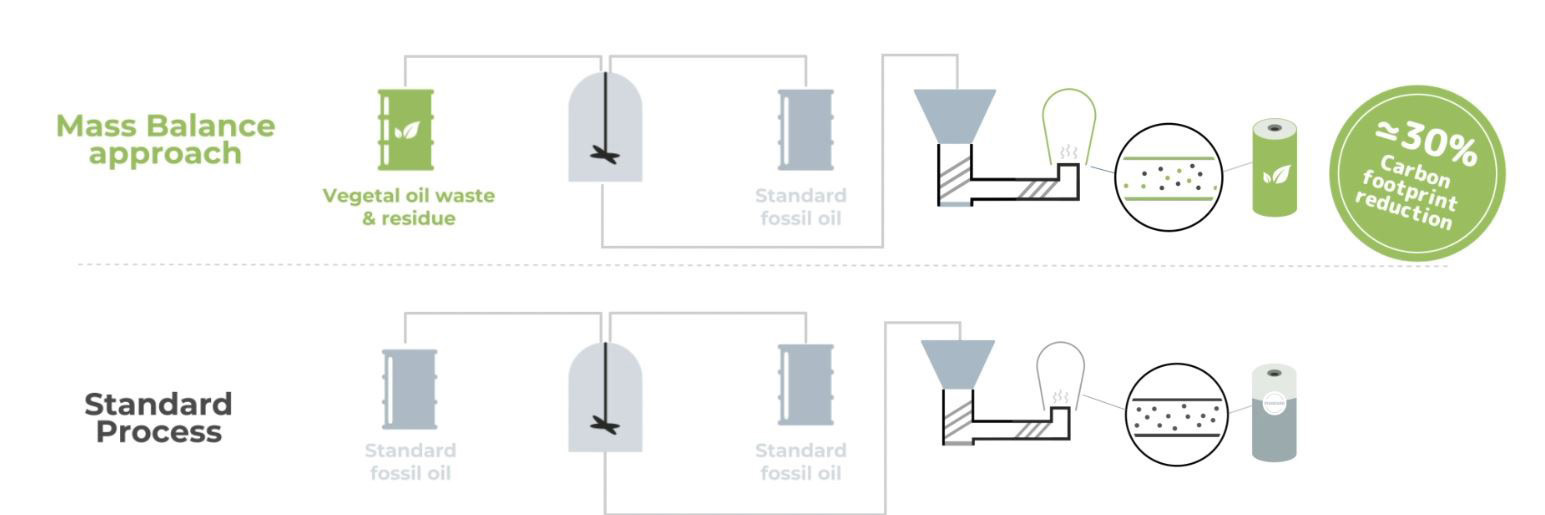

OXYGEN Vegetal è una linea prodotta grazie al mass balance approach.

Il mass balance approach è un principio universale: una percentuale di materiali viene sostituita da materie prime provenienti da produzioni responsabili, fin dalle prime fasi della lavorazione.

Per ogni metro quadrato di film OXYGEN Vegetal di Novacel, il 30% di polietilene a bassa densità (LDPE) o polipropilene è bio-sourced e viene miscelato nel processo produttivo dei nostri fornitori.

Il film OXYGEN Vegetal fa registrare la massima riduzione di emissioni di CO2

- ~30% di riduzione dell'impronta di CO2 rispetto a un film standard

- riciclabile*

![]()

*Riciclabile secondo i modi di riciclo definiti da ISO 472:2013 Plastics

Sostituisci subito il tuo prodotto standard

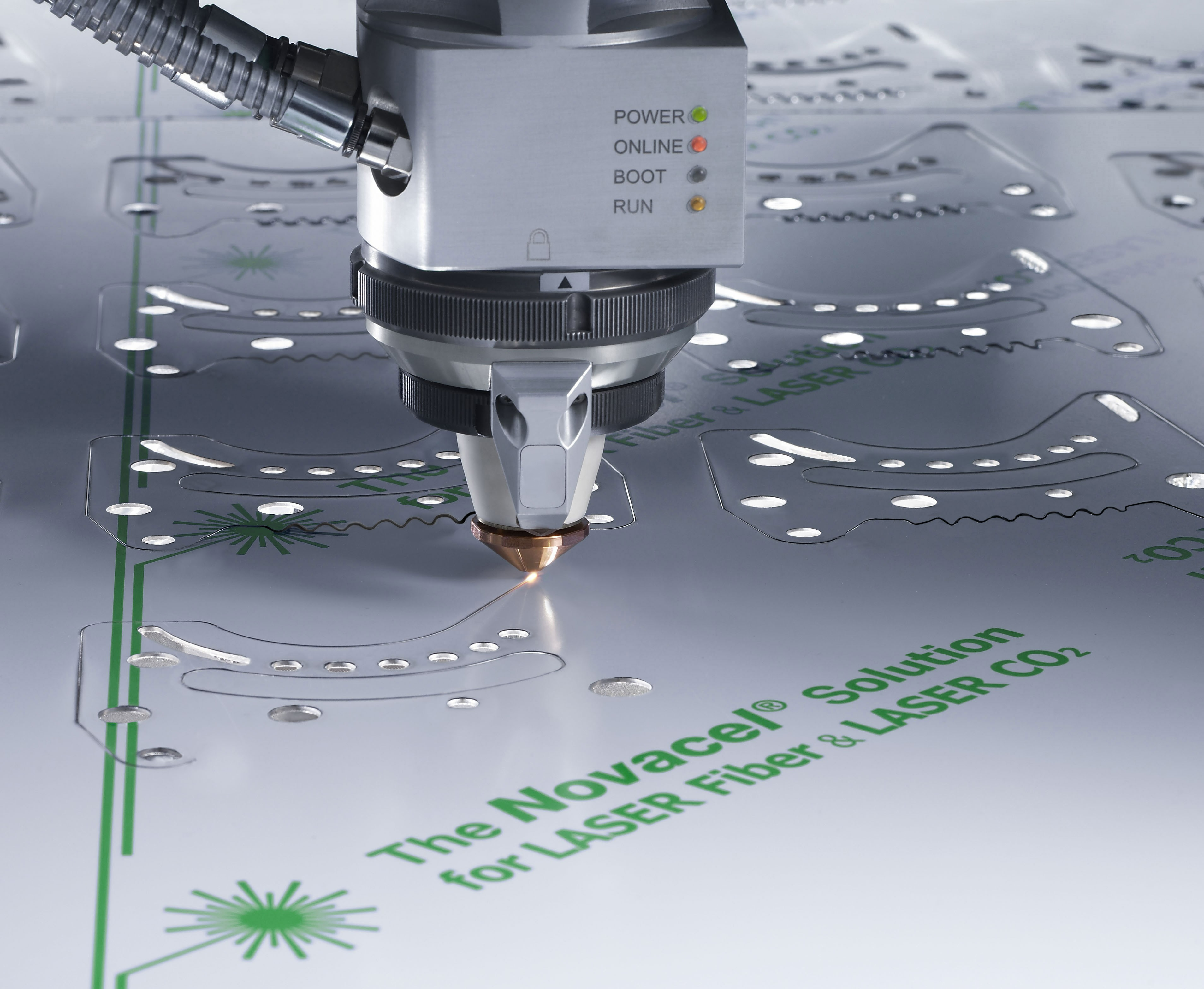

Questi film sono compatibili con tutti tipi di superfici: metallo, plastica, laminati, vetro... e anche con tutti i processi di trasformazione, anche quelli più impegnativi: foratura, stampaggio, schiumatura, profilatura e taglio.

Le caratteristiche sono uguali a quelle del tuo prodotto standard: proprietà meccaniche, adesività, resistenza ai raggi UV.

Passa subito dal tuo prodotto standard a Oxygen Vegetal. Ad esempio:

- Da 4233 a 3000 e approfitta sempre di 6 mesi di garanzia all’aperto

- Da 4228 a 3030 adatto a tutti i processi di taglio laser

Questi film sono anche stampabili. Utilizzali per comunicare il tuo impegno per l’ambiente.

Scopri tutti i film protettivi e industriali OXYGEN Vegetal!