OXYGEN Lean: i film protettivi e di processo ecologici

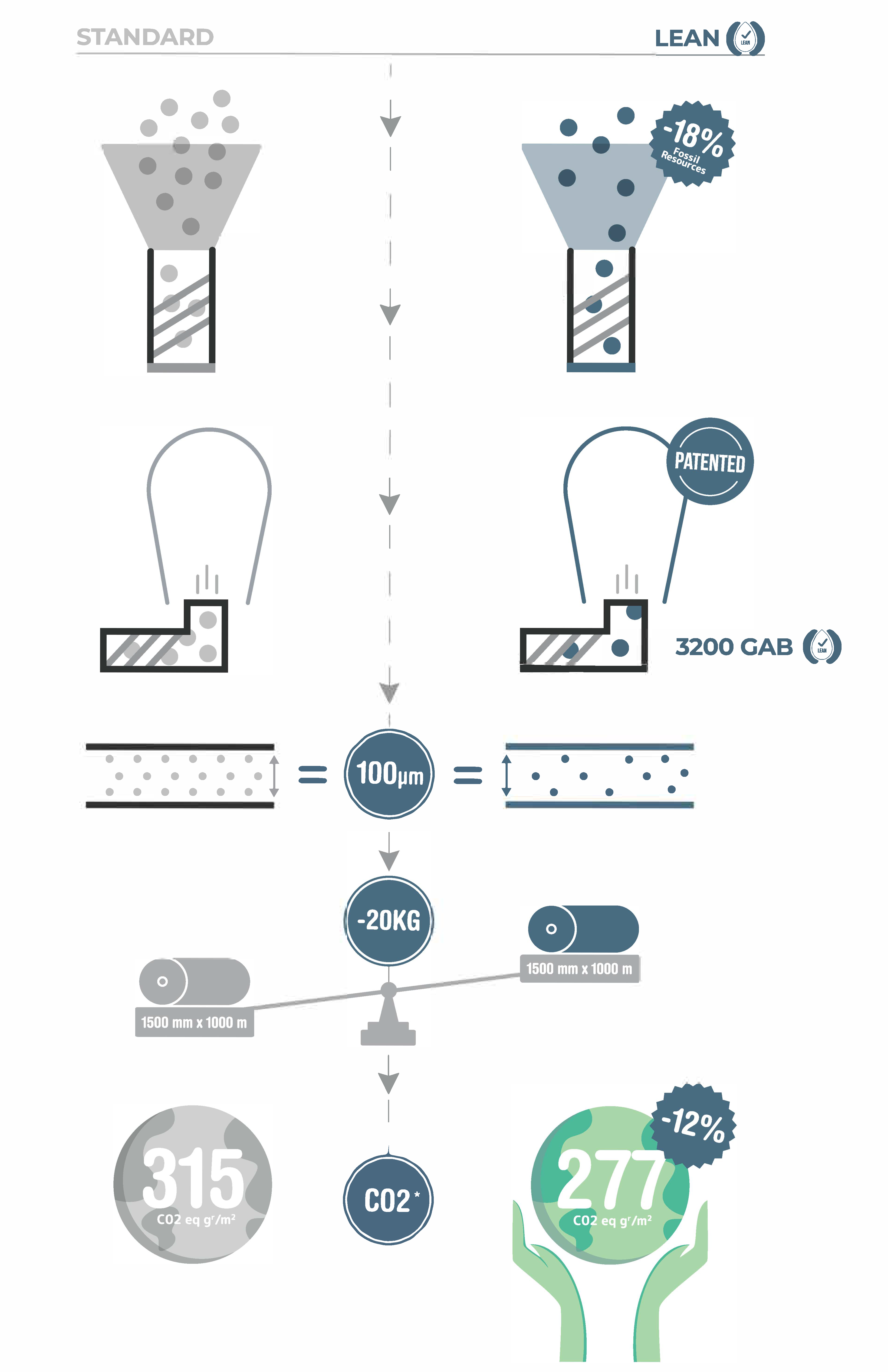

I film OXYGEN Lean sono il risultato di un processo di estrusione innovativo e brevettato.

Grazie a questa lavorazione unica nel suo genere, è possibile ridurre la quantità di LDPE contenuta nei film del 20% mantenendo lo stesso spessore.

Con la gamma OXYGEN Lean, Novacel aspira a ridurre l'impatto ambientale dei propri prodotti, ma non solo.

riduzione del ~20 % della quantità di LDPE, con tecnologia brevettata

L'innovazione della gamma Oxygen Lean consiste nell’aver mantenuto lo stesso spessore di un film tradizionale, riducendo considerevolmente la percentuale di risorse fossili impiegate.

Limitando la quantità di LDPE, si agisce sia sulla carbon footprint del prodotto che sul suo trasporto (ridotto grazie all'alleggerimento dei rotoli).

- Riduzione della carbon footprint rispetto a un film standard

- Rotoli più leggeri: riducono il peso del trasporto e migliorano la salute e la sicurezza dei lavoratori.

Si tratta quindi di una tecnologia utilissima che consente di raggiungere contemporaneamente obiettivi tecnici e ambientali.

![]()

Scopri tutti ifilm protettivi e industriali OXYGEN Lean!

OXYGEN Lean 3200GAB: dedicata al taglio laser

La soluzione 3200 GAB si basa sulla tecnica di estrusione LEAN, innovativa e brevettata. I vantaggi che offre sono innumerevoli:

- Rotoli più leggeri.

- Ad esempio, un rotolo da 100 kg peserà soltanto 80 kg grazie alla tecnologia Lean. Di conseguenza, anche i pallet risultano più leggeri. Significa una riduzione di 100 kg per un pallet da 5 rotoli.

- Miglioramento delle condizioni di salute e sicurezza per i lavoratori: carichi più leggeri da trasportare, meno lesioni alla schiena.

- Riduzione della carbon footprint

- Comunicazione diretta dei vantaggi per l’ambiente su film stampabile.

- riciclabile*

Pensata per i film più spessi, la tecnologia OXYGEN Lean è compatibile con una grande varietà di superfici: pannelli compositi in alluminio, metalli, plastica e può sopportare i seguenti processi di trasformazione:

- taglio laser a fibra

- taglio e foratura

- piegatura

- stampaggio

* Riciclabile secondo i modi di riciclo definiti da ISO 472:2013 Plastics

*L'elenco dei centri di raccolta e riciclo autorizzati è disponibile al paragrafo Servizi.