Films de protection et de process pour les métaux prélaqués

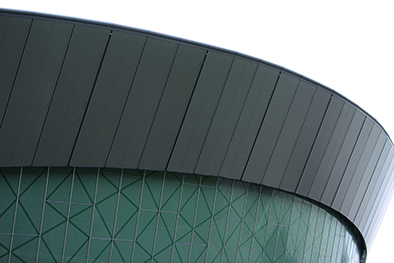

Les surfaces enduites en acier, en aluminium, en PVC stratifié ou co-stratifiées sont de plus en plus utilisées et sont désormais considérées comme des matériaux élégants et essentiels dans des secteurs comme l'architecture, le design, l'électroménager, l'industrie et le transport.

Grâce aux excellentes caractéristiques des produits parmi lesquelles une grande variété des structures et des coloris de leur surface ainsi qu'une usinabilité et une résistance à la corrosion excellentes, les métaux prélaqués répondent à toutes les exigences en matière de créativité. Ils garantissent la qualité des constructions en termes de fabrication et de durabilité.

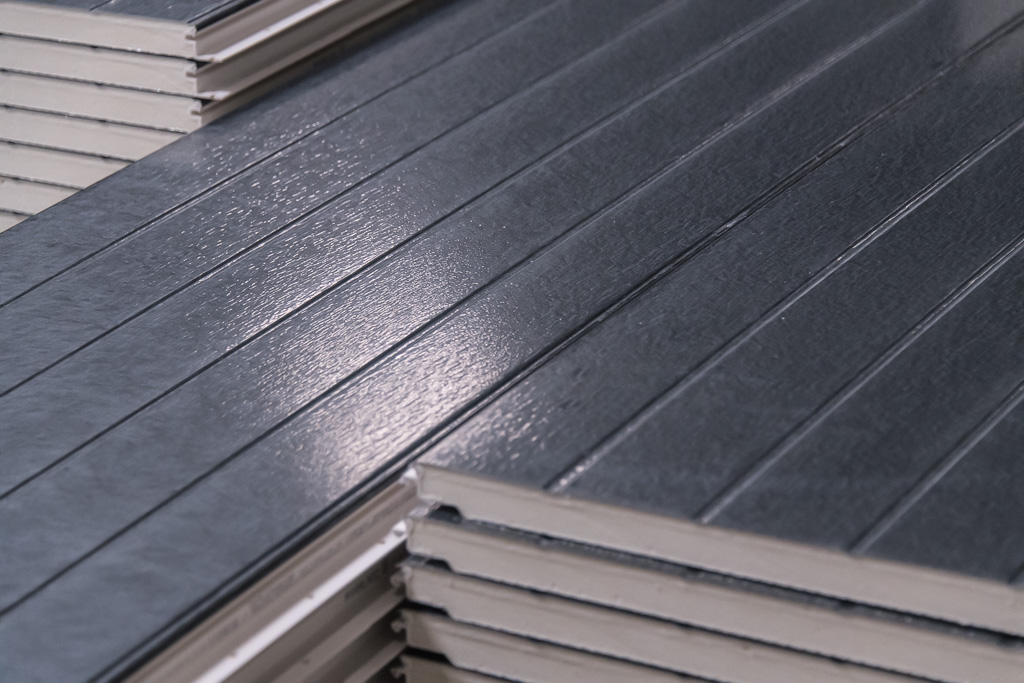

En coil ou en plaques, les métaux prélaqués subissent de multiples opérations de transformation avant de devenir des produits finis. L'intégralité du processus de fabrication est donc exigeant pour ces matériaux et ils nécessitent une solution adéquate pour éviter toute détérioration.

Téléchargez notre brochure pour en savoir plus sur nos solutions pour les métaux prélaqués.

Une solution pour chaque surface en métal prélaqué

Avec une gamme complète de films de protection et de process, allant de la technologie enduite à la technologie de coextrusion, Novacel vous apporte des solutions sûres et innovantes pour préserver l'intégrité de vos surfaces.

La gamme dédiée aux métaux prélaqués de Novacel est conçue pour une multitude de :

- Revêtements (polyester, polyuréthane, PVDF, plastisol, ayant des propriétés chimiques spécifiques comme la résistance aux UV, aux traces de doigts, aux graffitis, aux bactéries, aux reflets, à la saleté ou à la photoluminescence, etc.).

- Finitions des surfaces (lisses à structurées, avec une brillance ou une rugosité particulière).

- Processus industriels (profilage, pliage, sciage, refendage, perçage, broyage, moussage, découpe LASER fibre et LASER CO2, embossage, etc.).

- Secteurs (construction, électroménager, mobilier en général, électronique, etc.).

- Applications / utilisation finale (prélaquage en continu, bardage et revêtement de bâtiments, cassettes, panneaux sandwich pour façades - murs et toitures, cloisons, panneaux en aluminium, signalisation et affichages, boîtiers et pièces pour électroménager).

Parmi les principales caractéristiques que Novacel s'engage à vous offrir pour vous garantir une solution sûre et fiable, on trouve :

- des systèmes d'adhérence spécifiques et stables,

- une résistance optimale aux process mécaniques et thermiques,

- un retrait facile sans déchirure,

- une résistance extérieure considérable et dans le monde entier (1 à 12 mois),

- Recyclabilité

Olympeaks by Novacel : des solutions pour les métaux prélaqués texturés

Élaborée en partenariat avec des fabricants de peinture et des laboratoires d'enduction en continu, la gamme Olympeaks by Novacel est dédiée aux surfaces mates, rugueuses et à effet froissé.

Les innovations créatives tendent à privilégier les surfaces plus rugueuses, texturées et colorées que l'on retrouve sur des matériaux naturels.

Afin de répondre aux attentes du secteur de la construction, la gamme Olympeaks propose des solutions sur mesure pour le design architectural.

Olympeaks by Novacel couvre un vaste champ d'application, depuis les toitures jusqu'au fondations du bâtiment : tuiles, panneaux de bardage, gouttières peintes, panneaux sandwich, portes de garage, accessoires...

Toutes les références Olympeaks permettent d'obtenir un niveau d'adhésivité parfait, selon le tack et la forme demandés, pour correspondre ainsi aux procédés de fabrication qui suivront. Ils résistent à tous types de transformations pour faciliter le procédé de fabrication.

Opérations mécaniques, par exemple : profilage, embossage, poinçonnage, pliage.

Opérations thermiques et de moussage pour : des panneaux isolés (PIR/PUR/laine minérale), panneaux d'aluminium composite.

La gamme Olympeaks, comme l'ensemble des produits Novacel, respecte des valeurs fondamentales :

- Recyclable

- Conforme aux prérequis réglementaires de REACH

- Utilisations de composants sans phtalate

- Conforme à la réglementation sur la réduction du bruit (directives européennes et américaines)

Retirez le film de process facilement et rapidement

La gamme Easy Peel est une innovation historique de Novacel. Elle a été conçue pour être retirée extrêmement rapidement et facilement à la fin de la ligne de production, que ce soit par un retrait manuel ou automatisé.

Les films Easy Peel accompagnent les surfaces des métaux prélaqués au cours de toutes les étapes de fabrication et aident à réduire les déchets.

Novacel a conçu les gammes 4800 et 4254 afin de répondre aux attentes du marché mondial. Ces gammes à base d'eau uniques sont proposées en plusieurs épaisseurs et coloris, selon le niveau d'adhérence qui vous convient.

![]()

Comme tous les autres films Easy Peel de la gamme, ils se retirent sans effort, limitant ainsi le risque de troubles musculosquelettiques (TMS).

Les films Easy Peel de Novacel, ce sont des solutions innovantes qui préservent à la fois vos métaux prélaqués et vos collaborateurs !

En savoir plus sur l'expertise Easy Peel.

Une solution pour les procédés de découpe laser fibre

Découvrez les avantages des nouveaux films pour laser à fibre optique aux performances haut de gamme destinés aux métaux prélaqués :

- Une pellicule transparente unique pour identifier les coloris et inspecter les surfaces. L'impression spécifique est facilement identifiable pour la découpe LASER.

- Deux épaisseurs et deux niveaux d'adhérence pour s'adapter aux différentes finitions des métaux prélaqués (brillant/lisse, uni, métallique, structuré ou mat) : laqués (brillant/lisse, uni, métallique, structuré ou mat) : 4188REF est dédié à la construction et 4398REH est le bon choix pour l'électroménager.

![]()

Pour les applications avec une garantie extérieur, utilisez la gamme LASER standard (4228REF, 4329REH et 4318REM).

Profitez des meilleures solutions pour les métaux prépeints (primaire, peinture et vernis transparent), prêts pour le laser à fibre optique !

En savoir plus sur l'expertise de la découpe LASER.

Une solution pour les « Cool Colours » ou « PVDF »

Les peintures Cool Colours sont utilisées sur le marché des métaux prélaqués et sont principalement utilisées aux États-Unis. Un système de peintures PVDF haute performance pour les métaux utilisés en architecture.

Ces produits se caractérisent par leur couleur remarquable, leur durabilité et leur forte résistance à la lumière du soleil.

Cette technologie de peinture a en effet été spécialement formulée pour permettre au revêtement de réfléchir efficacement les rayons ultraviolets et l'aider à rester froid. Elle a recours à un système à double couche (revêtements de primaire et de finition).

Les finitions de peinture peuvent être standards ou plus structurées.

Découvrez la solution innovante de Novacel pour les peintures Cool Colours

Novacel 4857 / 4867 / 4069 / 4079 pour métaux prélaqués est une gamme conçue pour les finitions semi-mates et mates Cool Colours, avec deux niveaux d'adhérence et différentes couleurs (transparent/bleu).

La pellicule de haute résistance fournit une résistance mécanique efficace au cours des processus exigeants tels que le profilage.

PVDF est aussi appelé Kynar 500 est la marque de référence sur le marché. Il peut être appliqué sur l'acier ou sur les supports en aluminium sur les lignes de prélaquage en continu. Les systèmes de revêtement de ce type contiennent des résines PVDF et acryliques ainsi que des pigments céramiques.

La solution dernière génération pour les métaux prélaqués

Le film Novacel 4566 est conçu pour les surfaces lisses, brillantes, légèrement structurées et à finition satinée.

Transparent, résistant et polyvalent, il s'accompagne d'une garantie en extérieur de 3 mois dans le monde entier.

Adapté à de nombreuses applications standards telles que le profilage, le moussage, le pliage... et même les procédés les plus lourds.

Le nouveau Novacel 3186 est un film d'hiver que l'on peut retirer jusqu'à -20°C. Composé de 25 % de PE recyclé, il appartient à la gamme OXYGEN Recycled.

Transparent, il a une épaisseur de 30 µm et est garanti 3 mois en extérieur.

Ce film convient également aux finitions lisses, brillantes, légèrement structurées ou semi-mates.