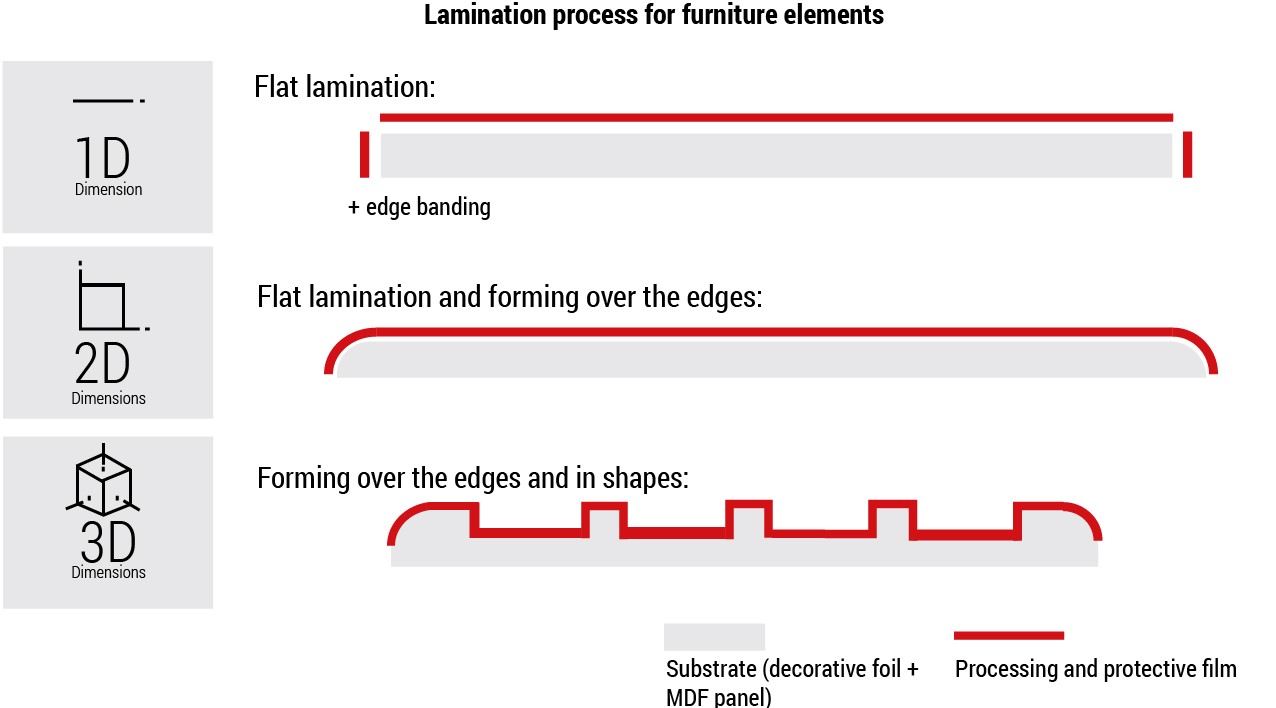

Processing and protective films for 2D/3D forming

Thermoplastic films and foils laminated or wrapped on a MDF (Medium Density Fiberboard) substrate are more and more used in the production of furniture elements.

The flexible process for furniture

1D (flat lamination), 2D (wrapping) and 3D forming (membrane and vacuum press) technologies offer many possibilities for shapes together with cost-effective industrial solutions for kitchens, bathrooms, living rooms, bedrooms, offices and shop fittings.

High-value furniture films and foils require premium quality processing solutions to withstand the whole process of fabrication of furniture's elements, ensuring perfect adhesion for sensitive high gloss, stylish silk aspects, as well as for the new super matt finish design.

Premium films for anti-fingerprint surfaces

Most of the decorative surfaces based on PP, PVC or PET foils and coextruded ABS/PMMA films, are often covered with a coating to get additional features such as improved scratch and chemical resistance, and recently the anti-fingerprint effect on new stylish matt finishes.

Novacel, as a pioneer and market leader in the furniture industry, engineered special high quality and low-gel content films coated with high-performance adhesive.

The visual assistance of online cameras during the process of adhesive coating ,ensure the best product quality, for a safe further processing of these aesthetic skins used in furniture fronts.

In recent years, thanks to its long expertise and know how in surface solution, Novacel has focused on the evolution of the furniture market, setting up partnerships with the key players to create innovative solutions chemically compatible with the new surface coatings.

Novacel 9120 and Novacel 4118 are the rising stars of the new trend in anti-fingerprint matt panels.

Novacel 4510 is the high-quality solution for high-gloss and satin panels with special chemical and scratch resistance.